2015 was my second full year tracking my pesticide use costs and EIQ in a detailed way. Overall I think my year was as good as can be expected as far as disease management goes. For the most part I was able to keep things under control and I came in under budget for costs and EIQ. As always I still only use pesticides on my putting greens which make up less than 1% of the total area of the golf course property (1 acre of 0.4ha).

In 2015 I spent less on pesticide for the golf course than any other year in recent memory. I think the reason why I was able to spend less this year was that we had a very dry summer and I was able to go from mid May to late August without a broadcast pesticide spray on my greens. I have had further success this fall with my last broadcast pesticide application occurring on Oct 23rd 2015. That's over 80 days ago!

This year I was made aware that the EIQ is a flawed method to determine the actual impact of pesticides on the environment. Here is an article that explains these flaws. Still, the EIQ is still somewhat better than using the mass of active ingredient applied as a measure of the environmental impact a specific product has. This is still the way that the vast majority of people track their pesticide use. Therefore I will still track EIQ as it is the best I have at the current time and will begin to look for new alternative methods to track pesticide impacts in a meaningful way.

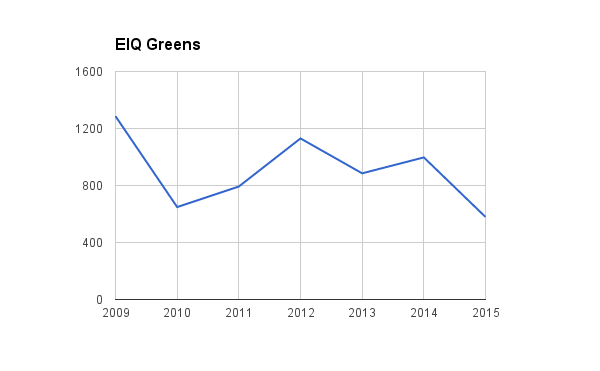

EIQ 2015 was also the lowest I have ever had. I could probably blow a bunch of smoke up everyone's ass and talk about how all my crazy schemes to reduce pesticide use have made an impact, and maybe they have. Obviously if you don't need to apply a pesticide there is no EIQ. The biggest reason I think my EIQ was so low this year was that I didn't need to use any chlorothalonil as we got a new contact fungicide in Canada called fludioxanil. The EIQ of a light chlorothalonil application is 300 where a fludioxanil is 14!

EIQ 2015 was also the lowest I have ever had. I could probably blow a bunch of smoke up everyone's ass and talk about how all my crazy schemes to reduce pesticide use have made an impact, and maybe they have. Obviously if you don't need to apply a pesticide there is no EIQ. The biggest reason I think my EIQ was so low this year was that I didn't need to use any chlorothalonil as we got a new contact fungicide in Canada called fludioxanil. The EIQ of a light chlorothalonil application is 300 where a fludioxanil is 14!

|

| 2010 was so low and 2009 so high because on the last day of 2009 I applied quintozene with an eiq of 833! |

Since 2009 my average EIQ for greens has been 900. Of that, 43% or almost 400 of my EIQ was from chlorothalonil or quintozene (no longer registered in Canada for turf). In 2015 chlorothalonil only accounted for 7% of my total EIQ as I only used it in my hand spray bottle in extremely small quantities. That's a 36% or a 324 point reduction in EIQ from chlorothalonil. Guess what? This year's EIQ was 321 points less than my average EIQ. Right there it's as simple as that.

I have continued to apply phosphite regularly whenever I apply fertilizer. The total EIQ from phosphite this year was 309 or 53% of my total EIQ! I wrote about how I don't think phosphite is necessarily an environmentally superior product in a blog past last spring. Either way, the mode of action of this product intrigues me and maybe it is the reason I have had so much success this year. It might also have a lesser environmental impact as I mentioned earlier the EIQ is flawed. Either way I will continue to use this product going forward.

Of course I could talk about all the things I have done. Despite the dry conditions this summer, I still had a lot of diseases show up on my greens. Brown Patch, Anthracnose, Waitea, Dollar Spot, and probably a lot more. The fact that I was able to manage these disease without the need for a broadcast pesticide application surely made an impact on my overall EIQ and certainly my costs for fungicides applied this year.

Each time I had a disease outbreak I would order up the product just in case things got carried away. By the time I got the product I usually had the disease under control and didn't require a corrective pesticide application. I guess this is one good thing about living in an isolated area where it takes a long time for product to arrive.

I have also developed a pretty high tolerance for disease on my course and am getting better at keeping my cool where in the past I would have panicked and played it safe. Experience is a beautiful thing...

So the EIQ reduction can be explained quite simply as a result of new products with a lesser EIQ coming into the market. The lower costs can be explained by my crazy disease management strategies and my unwillingness to apply preventative applications of a pesticide.

In the end it's easy to feel all warm and fuzzy and pat myself on the back, but in reality the success I had are due mostly to new safer products coming to market. I used to have an arrogance that could take all the credit but not so much anymore now that I understand just how complicated these things really are. My management strategies probably didn't make things worse which is important, but it's hard to say how much lower I can go in a consistent manner in the future. I guess we will have to wait an see. Fusarium is a worthy foe and I'm not sure what else can be done to eliminate the need for pesticides to control this beast during the winter.

I have continued to apply phosphite regularly whenever I apply fertilizer. The total EIQ from phosphite this year was 309 or 53% of my total EIQ! I wrote about how I don't think phosphite is necessarily an environmentally superior product in a blog past last spring. Either way, the mode of action of this product intrigues me and maybe it is the reason I have had so much success this year. It might also have a lesser environmental impact as I mentioned earlier the EIQ is flawed. Either way I will continue to use this product going forward.

Of course I could talk about all the things I have done. Despite the dry conditions this summer, I still had a lot of diseases show up on my greens. Brown Patch, Anthracnose, Waitea, Dollar Spot, and probably a lot more. The fact that I was able to manage these disease without the need for a broadcast pesticide application surely made an impact on my overall EIQ and certainly my costs for fungicides applied this year.

|

| The total extent of dollar spot on my greens in 2015 managed by applying urea light and frequently and managing moisture in soil or just plain dumb luck. |

|

| Waitea? Brown patch? Doesn't matter because with some soil moisture control, it went away. |

I have also developed a pretty high tolerance for disease on my course and am getting better at keeping my cool where in the past I would have panicked and played it safe. Experience is a beautiful thing...

|

| Footprints in the dew from disease scouting and spot spraying. |

In the end it's easy to feel all warm and fuzzy and pat myself on the back, but in reality the success I had are due mostly to new safer products coming to market. I used to have an arrogance that could take all the credit but not so much anymore now that I understand just how complicated these things really are. My management strategies probably didn't make things worse which is important, but it's hard to say how much lower I can go in a consistent manner in the future. I guess we will have to wait an see. Fusarium is a worthy foe and I'm not sure what else can be done to eliminate the need for pesticides to control this beast during the winter.